Why companies fall foul of over-engineering

Ever better functionalities, more standards, modularity and low total cost of ownership at a fair price: this is a short and concise summary of what companies in all industries expect from their machine and plant manufacturers and what the latter expect in turn from their parts and component suppliers. The consequence: the field of tension between engineering and controlling is growing. It is not only recently that the purchase department has been called upon to keep the purchase costs for outsourced parts or modules low. What many decision-makers are not aware of - despite the close dialogue with the purchasing department - is that the choice of supplier has a decisive influence on costs. Studies

[1] show that customers often generate additional costs when making a cost-driven decision between two suppliers.

However, there is also a phenomenon on the part of the contractor that has a negative impact on costs and can impair good business relationships between service provider and customer that have grown up over time: over-engineering. This white paper deals with what lies behind this phenomenon, where the possible causes lie and what solutions are available.

Cost trap: planning beyond the specification

At the beginning of product development, many companies do not consider in-house over-engineering as a cost driver. This can also be explained by the variety of interfaces - a technical dialogue between the customer's engineers and the supplier's design engineers is by no means a simple process. This has consequences, because

there is no such thing as the product development process. Companies think of flexibility and agility. For example, design engineers roughly orient themselves to what is taught in mechanical engineering studies.

[2]. This is the product development process based inter alia on the guidelines of the German Scientific Society for Product Development (WiGeP) and it is roughly divided into the following phases:

- Product planning (needs assessment, idea generation, feasibility study)

- Product development (dimensioning, design)

- Production (production planning, manufacturing, assembly, commissioning)

It is also striking that the product development process is rarely considered as part of the product life cycle. The consequence is that operation, maintenance and, last but not least, disposal or recycling of the product are not sufficiently considered. This also encourages over-engineering. A practical example

[3] illustrates the consequences: an engineer had to optimise a production concept. It was a fully automated process in which leakage sponges are inserted into an end product at a station. This process does not require a particularly high force - a classic pick-and-place process. However, according to the engineer, the base frame, the yoke plate and the columns supporting the pneumatic axes were designed as if the sponge had to be compressed with 10,000 Newton. According to the expert, a lighter and more cost-effective machine design would have been sufficient for the customer's requirements. The consequences were additional costs for material and construction. Added value was zero.

Without dialogue, constructive ideas can be too much of a good thing

It can be assumed that the dilemma could have been avoided by better communication. After all, whether a developed product actually meets all the customer's specifications can only be assessed after the sale and an evaluation of the sales figures and contribution margins. Although software tools, analyses and assumptions provide support in the planning phase, there is no certainty before commissioning and successful production.

This is a fine line for companies: they should neither develop products that go beyond the needs of their customers, nor must they stop wanting to improve their technologies.

It is now known that precise knowledge of customer requirements is needed to avoid over-engineering. Only the identification of customer interests protects against investing time and material in wrong developments. Simulation tools or so-called conjoint analyses can help.

Trending: customer surveys register requirements

Case studies

[4] clarify: a smart system for evaluating customer requirements is indispensable to counteract the constant cost pressure

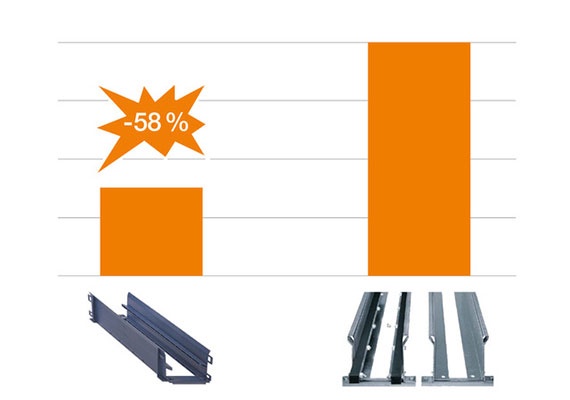

[5]. Based on this, the motion plastics® specialist igus® carried out an internal analysis in its target markets with the aim of developing products that come ever closer to the customer requirements and avoid over-engineering. The benefit for the industry is that either costs are reduced or more technology is available for the same amount of investment. By adjusting the parameters and the knowledge of customer needs and regulatory requirements, the total cost of ownership for the end customer is reduced in the best case.

The industry-wide survey, conducted by the business development and product managers of the motion plastics® specialist, highlights the factors that are most important to customers when buying components and machines:

- The strength of a product and the resulting longer service life

- Save even more installation space when a component is installed in the machine

- Reduce the noise level at a plant or in production

- Reduce the weight of a product

- Reduce the time required for installation on a system

- Minimise maintenance efforts/intervals of components/parts of the machine

- Reduce the total cost of ownership (procurement, operation, maintenance, disposal)

Surprising results and variety between the sectors

It is true that technical decision-makers in all sectors attach importance to strength and durability. However, the surveyed engineers from the areas of construction machinery, railways or offshore were not particularly interested in the required installation space of a component, which is only plausible in view of the plant size.

When it comes to noise, engineers in medical technology, automotive or aerospace industries in particular, attach importance to perfection, whereas for the other respondents it plays a rather less important role. Industries where noise is irrelevant use established standard components with a good price-performance ratio.

It is similar with the issue of weight: whereas it plays a central role for designers in aerospace technology, it is a secondary factor for engineers in other industries. Here too, the end customer can save costs in procurement and igus® can consciously counteract the over-engineering. It is astonishing that for almost half of all respondent companies from the total of 25 industries surveyed, the issue of installation time is less important and maintenance intervals also play a rather minor role.

Conclusion

The topic of over-engineering has arrived in industry. Instruments such as conjoint analysis support customers and service providers alike in walking the fine line between technical perfection and cost-efficient production. Industrial companies and suppliers can only survive in the increasingly tough global competition if they concentrate on their core competencies. This also includes active search and avoidance of over-engineering.

But not everywhere: in medical technology, for example, many products and technological systems are used directly on or in humans. Perfection, attention to detail and a little more safety are a priority. Here, experts in the industry certainly appreciate over-engineering.

[6]

[1] https://www.maschinenmarkt.vogel.de/sparen-im-einkauf-verursacht-erhebliche-mehrkosten-a-864291/ [2] Werner Skolaut (Hrsg.), Maschinenbau, Springer Verlag [3] https://www.wirtschaftswissen.de/einkauf-produktion-und-logistik/produktionsplanung/qualitaetsmanagement-produktion/schluss-mit-overengineering-warum-sie-stets-auf-adaequate-technologien-und-prozesse-setzen-sollten/ [4] https://www.tcw.de/news/optimierung-der-produktspezifikation-mittels-der-conjoint-analyse-980 [5] https://www.pwc.de/de/pressemitteilungen/2020/deutscher-maschinenbau-ist-und-bleibt-auch-2020-im-krisenmodus.html [6] https://www.ingenieur.de/karriere/arbeitsleben/arbeitssicherheit/over-engineering-fuer-vorteil/