Modificarea limbii :

iglidur® B - Date despre material

Tabelul de materiale

Specificații generale

Unitate

iglidur® B

Metoda de testare

densitate

g/cm³

1,15

Culoare

gri

max. Absorbția umezelii la 23°C/50% umiditate ambiantă.

% din greutate

1,0

DIN 53495

absorbție totală max. de umiditate

% în greutate

6,3

Coeficient de frecare la alunecare, dinamic, față de oțel

μ

0,18-0,28

Valoarea pv, max. (uscat)

MPa x m/s

0,15

Specificații mecanice

modul de flexiune

MPa

1.800

DIN 53457

rezistență la flexiune la 20°C

MPa

55

DIN 53452

Rezistență la compresiune

MPa

20

presiunea de suprafață maximă recomandată (20°C)

MPa

40

Duritate Shore D

69

DIN 53505

Specificații fizice și termice

Temperatura superioară de aplicare pe termen lung

°C

+100

Temperatura superioară de aplicare pe termen scurt

°C

+130

Temperatura inferioară de aplicare

°C

-40

conductivitate termică

W/m x K

0,24

ASTM C 177

coeficient de dilatare termică (la 23°C)

K-1 x 10-5

12

DIN 53752

Specificații electrice

Rezistivitatea de volum

Ωcm

> 1010

DIN IEC 93

rezistență de suprafață

Ω

> 109

DIN 53482

Tabelul 01: Date despre material

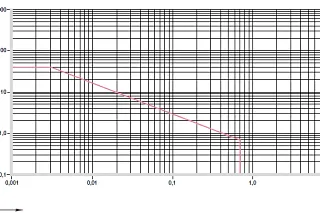

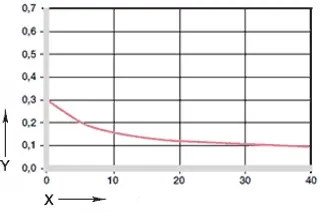

diagramă. 01: Valoarea pv admisă pentru rulmenții netezi iglidur® B cu grosimea peretelui de 1 mm în funcționare uscată împotriva unui arbore de oțel, la +20 °C, instalat într-o carcasă de oțel

X = viteza suprafeței [m/s]

Y = sarcina [MPa]

Rezistența la compresiune a rulmenților iglidur® B este scăzută, dar aceasta este o proprietate importantă a rulmentului. Acestea sunt utilizate în principal acolo unde sunt necesare amortizarea vibrațiilor și decuplarea acustică.

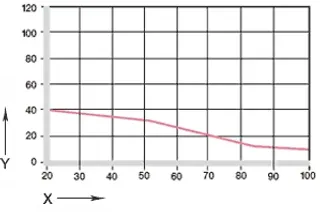

diagramă. 02: presiunea de suprafață maximă recomandată în funcție de temperatură (40 MPa la +20 °C)

X = temperatura [°C]

Y = sarcină [MPa]

Specificații mecanice

Presiunea superficială maximă recomandată reprezintă un parametru mecanic al materialului. Rezistența la compresiune a rulmenților iglidur® B scade odată cu creșterea temperaturii. diagrama 02 ilustrează această relație.

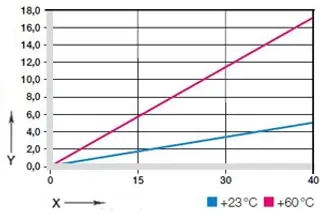

Diagrama 03: Deformarea sub presiune și temperatură

X = sarcină [MPa]

Y = deformare [%]

Deformarea la 40 MPa la temperatura camerei este de 5,3 % (diagrama 03).

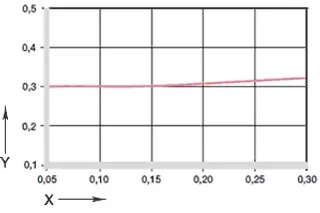

Diagrama 04: Coeficientul de frecare în funcție de viteza suprafeței, p = 0,75MPa

X = viteza suprafeței [m/s]

Y = coeficient de frecare μ

Frecarea și uzura

Coeficientul de frecare crește ușor cu viteza și scade cu sarcina. Rugozitățile arborelui între 0,4 și 0,6 Ra sunt ideale. Atât timp cât sarcina rulmentului nu este prea mare, valorile de uzură obținute sunt destul de bune. O creștere a sarcinii duce la o creștere disproporționată a uzurii.

Diagrama 05: Coeficientul de frecare în funcție de presiune, v = 0,01m/s

X = sarcină [MPa]

Y = coeficient de frecare μ

iglidur® B

Uscat

Grăsime

ulei

apă

coeficient de frecare µ

0,18 - 0,28

0,09

0,04

0,04

Tabelul 04: Coeficientul de frecare pentru iglidur® B față de oțel

(Ra = 1 µm, 50 HRC)

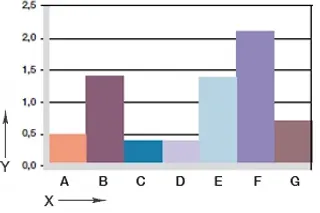

diagramă. 06: Uzură, aplicație rotativă cu diferite materiale ale arborelui, p = 1 MPa, v = 0,3 m/s

X = materialul arborelui

Y = uzură [μm/km]

A = aluminiu, anodizat dur

B = oțel de tăiere liberă

C = Cf53

D = Cf53, cromat dur

E = oțel carbon HR

F = 304 SS

G = oțel de înaltă calitate

Materialele arborelui

Influența materialului arborelui asupra rezistenței la uzură nu este foarte mare.

Diagramele 06 și 07 ilustrează faptul că se pot obține date de uzură foarte asemănătoare cu diferite materiale ale arborelui. Dacă se așteaptă performanțe de funcționare ridicate, sarcina pe rulment nu trebuie să fie prea mare.

Consultanta

Mi-ar face placere sa va raspund personal la întrebari

igus® GmbH+49 2203 9649-0Scrieti e-mail

Expediere și consultanță

În persoana:

Luni - Vineri de la 7 am la 8 pm.

Sâmbata de la 8 am la 12 pm.

Online:

24h