Modificarea limbii :

iglidur® - rezistență la uzură

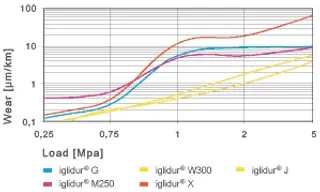

X = încărcare [MPa]

Y = uzură [μm/km]

diagramă. 13: Uzura rulmenților netezi iglidur®® la sarcină redusă, arbore: Cf53, v = 0,1 m/s

rezistența la uzură

Tocmai pentru că uzura pieselor de mașini depinde de atât de multe influențe diferite, este dificil să se facă afirmații generale cu privire la comportamentul la uzură. Prin urmare, în numeroase studii, uzura este, de asemenea, punctul central ca variabilă măsurată. Acest lucru arată diferențele care sunt posibile între diferitele perechi de materiale. Pentru o sarcină și o viteză de alunecare date, rezistența la uzură între perechile de materiale comune poate varia ușor cu un factor de 10.

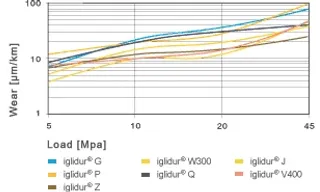

X = încărcare [MPa]

Y = uzură [μm/km]

diagramă. 14: Uzura rulmenților iglidur®® la sarcină medie și mare, arbore: Cf53, v = 0,1 m/s

Uzura sub sarcină

Sarcinile diferite au în mod natural o influență foarte puternică asupra uzurii rulmenților. Printre rulmenții netezi iglidur®, există specialiști atât pentru sarcini mici, cât și pentru sarcini mari sau extrem de mari. Cu arbori căliți și rectificați, iglidur® J poate fi descris ca fiind cel mai rezistent material de rulment la uzură pentru sarcini reduse. iglidur® Q, pe de altă parte, este specialistul pentru sarcini extreme.

Uzura și temperatura

În intervale largi de temperatură, rezistența la uzură a rulmenților iglidur® se modifică doar ușor. În intervalul superior de temperatură, însă, influența temperaturii crește și uzura rulmenților crește disproporționat.

Tabelul 06 compară așa-numitele limite de uzură.

O excepție specială aici este iglidur® X. Rezistența la uzură a rulmenților din iglidur® X crește inițial foarte puternic și atinge valoarea optimă la o temperatură de +160°C. După aceea, aceasta scade, inițial doar ușor. După aceea, scade din nou, inițial doar ușor.

| Material | Temp. [°C] |

|---|---|

| iglidur G | +120 |

| iglidur J | +70 |

| iglidur M250 | +80 |

| iglidur W300 | +120 |

| iglidur X | +210 |

| iglidur K | +90 |

| iglidur P | +100 |

| iglidur GLW | +100 |

| iglidur J260 | +80 |

| iglidur J3 | +70 |

| iglidur J350 | +140 |

| iglidur L250 | +120 |

| iglidur R | +70 |

| iglidur J200 | +70 |

| iglidur D | +70 |

| iglidur V400 | +130 |

| iglidur X6 | +210 |

| iglidur Z | +200 |

| iglidur® UW500 | +190 |

| iglidur H | +120 |

| iglidur H1 | +170 |

| iglidur H370 | +150 |

| iglidur H2 | +120 |

| iglidur A180 | +70 |

| iglidur A200 | +80 |

| iglidur A350 | +120 |

| iglidur A500 | +190 |

| iglidur A290 | +120 |

| iglidur T220 | +90 |

| iglidur F | +130 |

| iglidur H4 | +120 |

| iglidur Q | +80 |

| iglidur UW | +70 |

| iglidur B | +70 |

| iglidur C | +70 |

Consultanta

Mi-ar face placere sa va raspund personal la întrebari

igus® GmbH+49 2203 9649-0Scrieti e-mail

Expediere și consultanță

În persoana:

Luni - Vineri de la 7 am la 8 pm.

Sâmbata de la 8 am la 12 pm.

Online:

24h