Modificarea limbii :

drylin® W - Instrucțiuni și reguli de proiectare

Rulmenți plutitori pentru sisteme de ghidare

Egalizarea automată a erorilor de paralelism,

Primul rulment flotant, al doilea rulment fix

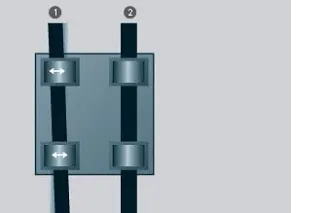

Atunci când se utilizează sisteme cu două ghidaje paralele, una dintre părți trebuie să fie proiectată ca un rulment flotant. Există o soluție adecvată de rulment fixat/nefixat pentru fiecare poziție de instalare, fie orizontală, verticală sau laterală. Această metodă de instalare previne rigidizarea sau blocarea ghidajului în cazul unor deviații de paralelism între ghidaje. Rulmentul plutitor este realizat prin extinderea controlată a jocului în direcția erorii de paralelism anticipate. Acest lucru creează un grad de libertate suplimentar pe o parte.

În timpul instalării, este important să se asigure că rulmentul flotant are aproximativ aceeași cantitate de joc în ambele direcții. Designul sistemului de rulment flotant fix recomandat de noi poate fi văzut în ilustrațiile de mai jos. Suprafețele de racordare pentru ghidaje și cărucioare trebuie să aibă o bună planeitate (de exemplu, suprafață frezată) pentru a evita tensiunile în sistem. Micile denivelări ale suprafețelor de legătură pot fi compensate într-o anumită măsură prin rulmenți plutitori.

Rulmenții plutitori ajută la asamblare - atunci când se utilizează șine simple

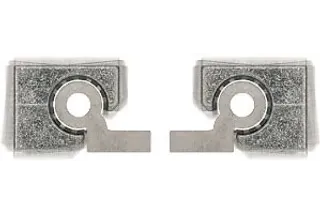

rulment plutitor, selectabil în toate direcțiile (+/- 1 mm), compensează nealinierea și paralelismul.

Utilizatorii pot reduce munca de instalare cu profilul pătrat drylin® W. Rulmenții plutitori, care pot fi selectați în toate direcțiile (+/1 mm), compensează dezalinierea și paralelismul dintre șine. Blocajele, care altfel pot fi prevenite doar prin alinierea paralelă a sistemului, care necesită mult timp, pot fi excluse.

Deși drylin® W este un sistem de șine profilate, erorile de unghi în jurul axei x pot fi compensate. Un unghi de +/- 7° este disponibil în acest scop. Acest lucru elimină în mod eficient distorsiunile cunoscute din asamblarea pieselor din tablă.

Forțe excentrice

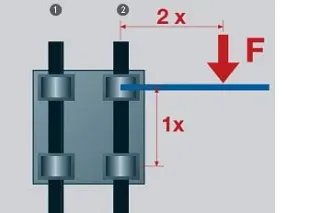

Regula 2:1,

Primul rulment flotant, al doilea rulment fix

Trebuie respectate câteva recomandări pentru utilizarea cu succes a rulmenților liniari fără întreținere drylin® **: ** Dacă distanța dintre forța de antrenare și rulmentul fix este mai mare de două ori decât distanța dintre rulmenți (regula 2:1), un coeficient de frecare statică de 0,25 conduce teoretic la blocarea ghidajului.

Principiul nu depinde de sarcină sau de forța de antrenare. Acesta este un produs al frecării și se referă întotdeauna la rulmentul de fixare. Cu cât acționarea este mai îndepărtată de rulmentul de ghidare, cu atât uzura și forța de acționare necesară sunt mai mari.

Dacă regula 2:1 nu este respectată atunci când se utilizează rulmenți liniari, rezultatul este o mișcare neuniformă sau chiar blocarea sistemului. Acest lucru poate fi adesea remediat cu modificări relativ simple.

Dacă aveți întrebări cu privire la proiectare și/sau instalare, vă rugăm să contactați consultanții noștri pentru aplicații.

Consultanta

Mi-ar face placere sa va raspund personal la întrebari

igus® GmbH+49 2203 9649-0Scrieti e-mail

Expediere și consultanță

În persoana:

Luni - Vineri de la 7 am la 8 pm.

Sâmbata de la 8 am la 12 pm.

Online:

24h